- Testing

- Morphology Observation

- Microstructure Analysis

- Surface Element Analysis

- Surface Foreign Body

- Component Analysis

- Mechanical property test

- Thermal Analysis

- Welding Qualification

- CT Scan

- Nondestructive testing

- Cross Section Analysis

- Coating Thickness

- Flame Retardant Test

- Abration Test

- Coating quality inspection

Horizontal Flammability Test

| Vertical Flammability Test | The Oxygen Index Test |

| Glow Wire Test | Horizontal Flammability Test |

| Needle-flame Test | Flammability of Interior Materials |

Test standard:

UL94-2015, 4943.1-2011 GB, 2408-2008 GB/T, 5169.16-2008 GB/T, etc..

Scope:

Plastic, foam, film, textile, paint, rubber, etc., are not applicable to building materials.

Sample size:

Length 125±5mm, width 13±0.5mm, thickness 0.025~13mm

Test pretreatment:

A set of 3 samples at23±2℃, 50±5%RH adjustment at least 48H

Tested Condition:

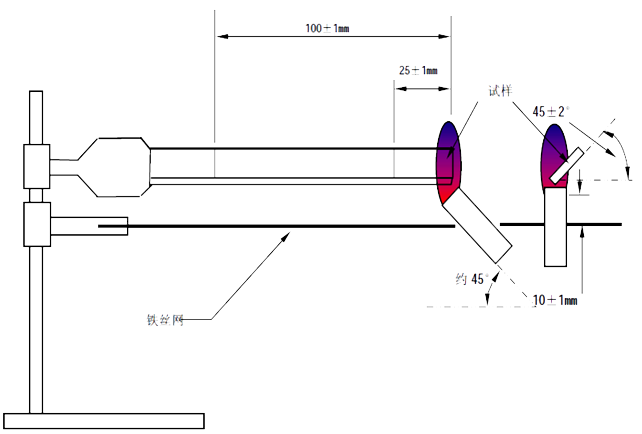

The flame height is 20±1mm, the ignition time is 30±1s, the flame source is tilted 45 degrees, and the sample holder is kept at 45 degrees with the horizontal plane.

HB Criteria:

1)Not have a burning rate exceeding 40mm per minute over a 75mm span for specimens having a thickness of 3.0~13mm, or

2)Not have a burning rate exceeding 75mm per minute over a 75mm span for specimens having a thickness less than 3.0mm, or

3)Cease to burn before the 100mm reference mark.

4)A material classified HB in the 3.0+0.2 mm thickness shall automatically be classed HB down to a 1.5 mm minimum thickness without additional testing.

Test schematic diagram

Case:

Typical cases

Reference standard:

Fuel test for plastic materials for UL94-2015 equipment and appliances.

Tested Flow:take picture→mark on specimens at 25mm and 100mm→set parameters of instrument→start testing

Tested Condition:

Level of combustion flame height requirement is 20 ± 1mm, the ignition time is

30±1s, Flame source tilt 45 °, with the level of the sample holder maintained between 45 °.

Sample Size:127mm×13mm×4.4mm

HB Criteria:

1)Not have a burning rate exceeding 40mm per minute over a 75mm span for specimens having a thickness of 3.0~13mm, or

2)Not have a burning rate exceeding 75mm per minute over a 75mm span for specimens having a thickness less than 3.0mm, or

3)Cease to burn before the 100mm reference mark.

4)A material classified HB in the 3.0+0.2 mm thickness shall automatically be classed HB down to a 1.5 mm minimum thickness without additional testing.

Test result:

| Test sample | test result(mm/min) | ||

|---|---|---|---|

| --------- | 1 | 30.1 | |

| 2 | 32.5 | ||

| 3 | 28.7 | ||

| Maximum value | 32.5 | ||

Conclusion:The samples comply with UL94-2015 HB.

- Learn more

- Qualification and honor

- Contact Us

- Contact Us

MTT Shenzhen

Tel: 400-850-4050

Fax: 0755-2782 1672

Email: marketing@mttlab.com

MTT Suzhou

Tel: 400-118-1002

Fax: 0512-6275 9537

Email: marketing@mttlab.com

MTT Shanghai

Tel: 400-118-1002

Email: marketing@mttlab.com

MTT Dongguan

Tel: 400-116-1002

Email:marketing@mttlab.com