- Testing

- Morphology Observation

- Microstructure Analysis

- Surface Element Analysis

- Surface Foreign Body

- Component Analysis

- Mechanical property test

- Thermal Analysis

- Welding Qualification

- CT Scan

- Nondestructive testing

- Cross Section Analysis

- Coating Thickness

- Flame Retardant Test

- Abration Test

- Coating quality inspection

Product Anomaly Comparative Analysis

| Organic Foreign Body Analysis | Inorganic Foreign Body Analysis |

| Unknown Foreign Body Analysis | Product Anomaly Comparative Analysis |

Usually the individual components of polymeric materials happen to change even the change of material types, it is difficult to identify from the outside. However, subtle differences in the material may cause some performance degradation, which does not meet the requirements of standard or results in lower-quality product or due to changes in production technology or changes in raw material procurement lead to changes in the quality of final product. Product anomaly comparative analysis is the use of molecular mapping characteristics of materials, to develop rapid detection method and determine the consistency of product material so as to analyze the reason of abnormal phenomenon of product. Analyzing the consistency of the product materials will generally apply to the following characteristics of polymer materials:

1.Different materials have different molecular fingerprint region of the infrared spectra and molecular fragments pyrolysis map.

2.The molecular weight of recycling of polymeric materials will decline which causes the glass transition temperature of the material, the degree of crystallinity, the melting temperature and decomposition temperature change.

3.Pigment to binder ratio and the change of the fillers will be reflected in the thermo-gravimetric changes in polymer materials, and showed in the final residual ash.

4.Change of polymer materials will generally result in specific gravity (or density) changes.

| Analysis methods | Typical applications | Characteristics of analysis | The reference standard |

|---|---|---|---|

| Infrared spectrum (FTIR) | Qualitative organic matter; Analysis of organic pollutants | Micro are analysis can be done; the microscopic measurement aperture can be 8μm or less; according to the requirements to choose the part of sample for analysis. | GB/T 6040-2002 |

| TGA (thermogravimetric method) | The content of filler in polymer materials | High accuracy, fast speed and sensitivity Microvolumelization of tested sample, | ASTM E2550-2007 |

| Differential scanning calorimetry (DSC) | Measure the glass transition temperature, melting, crystallization, curing reaction, specific heat capacity and thermal history | Sensitivity, high resolution, good reproducibility, less sample consumption. | ASTM E1356-2008 |

Case analysis:

Case background:

A customer finds a batch samples appear cracking phenomenon in the use process and he suspects the consistency of the product.

Testing methods:

FTIR analysis, TGA analysis, DSC analysis

Testing standards:

GB/T 6040-2002 The general principles of the infrared spectrum analysis method

ASTM E1356-2008 Measurement of glass transition temperature by differential scanning calorimetry and differential thermal analysis

ASTM E2550-2007 Standard Test Method for determination of thermal stability by thermogravimetric analysis

Introduction of analysis methods:

1.OK sample and NG sample appearance are completely consistent, selecting the OK products and NG products through the fingerprint analysis to determine the consistency of the material;

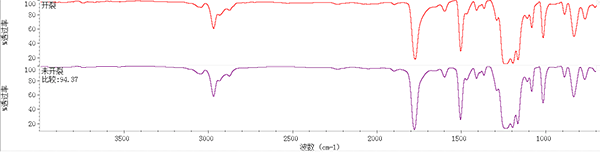

2.FTIR test analysis shows that the main components of the sample are polycarbonate (PC). The similarity between OK and NG samples is 94.37%;

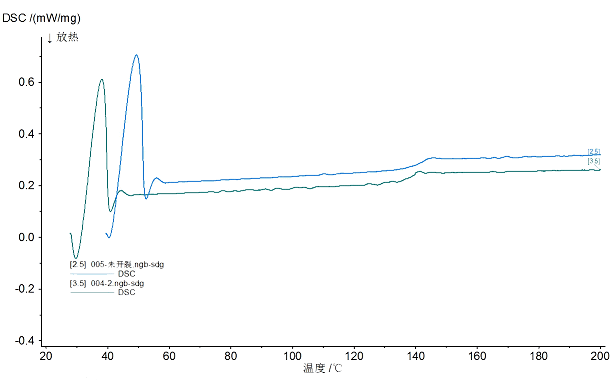

3.DSC curve shows that: NG sample a glass transition temperature is 139.8 ℃; OK sample glass transition temperature is 143.3 ℃;

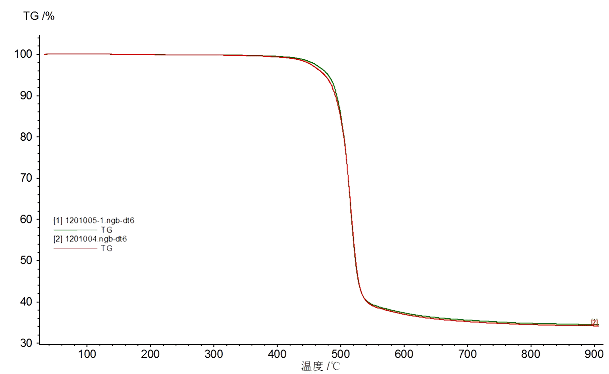

4.GA curve shows that: the quantity of sample NG is 63.73%; the degradation of the sample 1201005 change amount is 63.37%; sample OK residual quantity is 34.17%, sample 1201005 residual amount is 34.50%.

Conclusion:

Based on the above FTIR, DSC, TGA comprehensive analysis of test results, the materials of OK and NG are consistent and have no significant difference.

- Learn more

- Qualification and honor

- Contact Us

- Contact Us

MTT Shenzhen

Tel: 400-850-4050

Fax: 0755-2782 1672

Email: marketing@mttlab.com

MTT Suzhou

Tel: 400-118-1002

Fax: 0512-6275 9537

Email: marketing@mttlab.com

MTT Shanghai

Tel: 400-118-1002

Email: marketing@mttlab.com

MTT Dongguan

Tel: 400-116-1002

Email:marketing@mttlab.com